-

Products

- Lab Instruments

-

Lab Meters and Probes

Calibration Standards Other Meters and ProbesOther Reagents

- Chemistries, Reagents, and Standards

-

Online Analyzers

Ammonium Analysers Chlorine Analyzers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analog)

- SC4500

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Pro Series

pH & ORP Sensors- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

Dissolved Oxygen Sensors- 5500 Clark DO

- 9582 sc

- LDO 2 sc

- Orbisphere 311xx

- Orbisphere GA2x00

- Orbisphere K1X00

- Orbisphere M1100

- Orbisphere Oxygen ppb

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 3798 sc Electrodeless

- 9523 Cation Conductivity

- 9525 DCCP System

- Samplers

- Multiparameter Online Panels

- Test Kits & Strips

-

Microbiology

Accessories and Chemicals Dehydrated MediaInstruments KitsLabware

- Automated Lab Systems

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments- Balances

- Hot Plates & Stirrers

- Microscopes

- Moisture Analysers

- Other Instruments

- Ovens & Incubators

- Refractometers

- Thermometers

- Timers

- Vacuum Pump

- Water Purification Systems

- Industrial UV

- Parameters

- Industries

- Service & Support

- Brands

- e-Shop

Hach India

Choose your country or region:

Europe

Americas

Asia - Australasia

- Australia

- Mainland China

- India

- Indonesia

- Japan

- Malaysia

- New Zealand

- Philippines

- Singapore

- South Korea

- Thailand (Thai)

- Taiwan

Middle East - Africa

Chemistries INQUIRY: +91 9916040249 - e-Shop: +91 63668 87212

Dissolved Oxygen

Why Monitor Dissolved Oxygen (DO)?

Measuring dissolved oxygen in water, and treatment to maintain proper dissolved oxygen levels, are crucial functions in a variety of water treatment applications. While dissolved oxygen is necessary to support life and treatment processes, it can also be detrimental, causing oxidation that damages equipment and compromises product. Dissolved oxygen (DO) affects:

-

Quality–The DO concentration determines the quality of source water. Without enough DO, water turns foul and unhealthy affecting the quality of the environment, drinking water and other products.

-

Regulatory Compliance–To comply with regulations, wastewater often needs to have certain concentrations of DO before it can be discharged into a stream, lake, river or waterway. Healthy waters that can support life must contain dissolved oxygen.

-

Energy Consumption Cost–Effectively monitoring DO can reduce costs by making processes more efficient.

-

Process Control–DO levels are critical to control biological treatment of wastewater as well as the biofiltration phase of drinking water production.

At Hach, find the testing equipment, resources, training and software you need to successfully monitor and manage Dissolved Oxygen (DO) levels in your specific process application.

What is Dissolved Oxygen (DO)?

Dissolved oxygen is a measure of the amount of gaseous oxygen contained in water. Healthy waters that can support life must contain Dissolved Oxygen (DO).

Dissolved Oxygen (DO) Enters Water by:

- Direct absorption from the atmosphere.

- Rapid movement from winds, waves, currents or mechanical aeration.

- Aquatic plant life photosynthesis as a byproduct of the process.

Factors that Contribute to the Concentration of Dissolved Oxygen (DO) in Water:

- Atmospheric pressure: Higher atmospheric pressure allows bodies of water to retain more Dissolved Oxygen. The pressure from above allows the water to hold more oxygen atoms. On the other hand, DO concentrations are normally lower at higher elevations due to lower atmospheric pressure.

- Temperature: A body of water with lower temperature can contain more dissolved oxygen because oxygen atoms have less movement. The increased movement of oxygen atoms in warmer water, allows them to escape out of the water into the air.

- Depth of the water: The shallower the water, the higher the concentration of DO because wind creating waves on the surface increases DO and algae and other aquatic plants that live in shallower light filled waters also creates DO as a by-product of photosynthesis.

- Salinity: Lower salinity contributes to a higher concentration of DO because salts affect the solubility of gases essentially driving the oxygen atoms out of the water.

- Bioactivity: Lower bioactivity of microorganisms in water leads to a higher concentration of DO because microorganisms feeding on organics and decaying matter use oxygen in their respiration.

Featured Products for Monitoring Dissolved Oxygen (DO)

LDO 2 sc Luminescent Dissolved Oxygen Sensors

Hach’s next generation LDO® (Luminescent Dissolved Oxygen) Probe requires no calibration for the entire 2 year life of the sensor cap, which means it is ready to start measuring your DO (Dissolved Oxygen) right out of the box.

Shop NowHQ Series/HQD Meters/Intellical Probes

The rugged and durable HQD® portable meters and laboratory meters are designed to give drinking water and wastewater professionals the greatest confidence and flexibility.

Shop NowRed Rod pH probes offer exceptional performance and response time across a wide variety of sample types in the laboratory. Rugged stainless steel outdoor probes are extremely practical for on-site analysis.

Shop NowOrbisphere K1100/K1200 Oxygen Sensors

Orbisphere K1x00 Sensors are maintenance-free, optical Luminescent Dissolved Oxygen Sensors designed for monitoring oxygen in power plants. The K1x00 series also includes a sensor version for nuclear power applications.

Shop NowOrbisphere M1100 Oxygen Sensors

The Orbisphere M1100 optical sensor, together with the Orbisphere 410 one channel and the Orbisphere 510 multi-channel controller, offers a new way of monitoring oxygen in the beverage production process.

Shop Now9582 sc Dissolved Oxygen Sensors

9582 sc Dissolved Oxygen Sensors are designed for ppb-level measurements in ultrapure water, boiler water and condensate. They are an integral part of a complete water analytics system designed for the Power industry.

Shop Now

Which Processes Require the Monitoring of Dissolved Oxygen (DO)?

Wastewater Treatment

-

Influent water entering a facility has a low DO concentration because it contains organics and microorganisms which consume oxygen (while feeding on the organics).

-

DO levels need to be replenished in effluent water leaving the facility in order to meet minimum DO level requirements to protect ecosystems and to comply with regulatory discharge permits. These regulations ensure that effluent water does not deplete oxygen levels in receiving waterways.

-

Monitoring DO helps promote efficiency in aeration basins. By using online DO measurement equipment, a facility can reduce energy costs by adjusting aeration to match the DO required by the organic load. Continuous measurement and adjustment ensure that the microorganisms have enough oxygen to consume organics while allowing the facility to conserve energy by reducing aeration when possible.

Industrial Steam Generation

Because DO causes corrosion in equipment, achieving low or no DO can prevent leaks failures and shutdowns.

Drinking Water Treatment

-

It is important to maintain a balanced concentration of DO in finished water discharged into the distribution system.

-

Monitoring of DO in source water can provide early warning for seasonal rise in manganese concentration.

-

High levels of DO accelerates corrosion in water pipes.

-

Low levels of DO can cause an increase in ferrous iron concentration resulting in discoloration at the tap when water is aerated.

-

Balanced DO can improve the taste of drinking water.

Beverage Industry

-

Soft Drink corporations set quality standards for DO levels to stabilize taste, to ensure shelf-life and to avoid corrosion in the packaged cans.

-

Breweries monitor DO because fermentation requires oxygenation. However, for packaging low DO levels are necessary to improve shelf-life and to stabilize taste/odor.

-

Wine Producers maintain low DO content to prevent oxidation, loss of aroma, discoloration, rapid aging and the growth of microorganisms.

-

Juice Producers maintain low DO to ensure flavor stability.

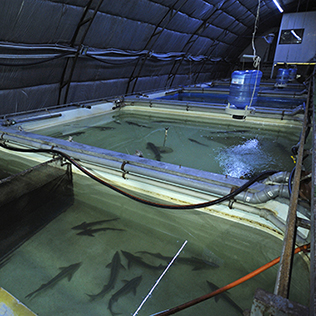

Aquaculture

In aquariums and on fish farms a minimum DO level of 4.5 mg/L is necessary to support fish life. Too much DO can result in disease.

Environmental Monitoring

Without a healthy concentration of DO a body of water can experience hypoxia–a condition in which there is not enough oxygen to support aquatic life that leads to die offs.

How is Dissolved Oxygen Monitored?

Because DO is a gas in water it must be measured on site, ideally in the body of water. Drawing a sample introduces atmospheric oxygen into the sample interfering with the accuracy of the measurement.

Electrodes:

The most common, expedient, and easiest method, electrodes offers lab, portable and online process options. This method uses optical or electrochemical sensors to measure DO in water.

Optical Electrodes:

This method uses light and luminescent material to measure DO. These electrodes require less maintenance, hold calibration, are not affected by hydrogen sulfide or other gases. They offer accuracy, stability and reproducibility and 60 second response times.

Electrochemical Electrodes:

This method utilizes Galvanic or Polarographic electrodes (anode and cathode in an electrolyte solution) to measure DO. To ensure accuracy the electrodes require frequent calibration and water samples must be gently stirred.

Colorimetric Method:

Indigo carmine reacts with the DO in the water producing a blue color proportional to the DO concentration. The blue color can then be visually compared to a chart or read with a colorimeter or spectrophotometer. This method is portable for field-use, but it has limitations. The water must be transparent and free of particulates.

Winkler Titration:

This method is performed by adding chemicals (Manganese, iodide & hydroxide) to water samples to create a reaction with the DO that forms an acid solution. The amount of neutralizing agent required to neutralize the acid with titration indicates how much DO was in the original water sample. Though it is considered a traditional method in some areas, it is time consuming and subject to human error. No Online process exists for this method.

Frequently Asked Questions

How can monitoring dissolved oxygen save my treatment plant money?

Up to 70% of a Wastewater plant’s energy budget is spent powering their aeration system. For years, these aeration systems were controlled by manually changing the airflow set point, valve positions, or speed of the motor because membrane DO sensors were unreliable. LDO allows the systems to automatically control the aeration system to a certain DO set point—allowing the aeration system to respond to the loading in real time, saving 30 to 60% in energy costs.

Why is dissolved oxygen important?

Dissolved oxygen (DO) is necessary to many forms of life including fish, invertebrates, bacteria, and plants. These organisms use oxygen in respiration, like organisms on land. Fish and crustaceans obtain oxygen for respiration through their gills, while plant life and phytoplankton require dissolved oxygen for respiration when there is no light for photosynthesis. The amount of dissolved oxygen needed varies from creature to creature. Bottom feeders, crabs, oysters and worms need minimal amounts of oxygen (1-6 mg/L), while shallow water fish need higher levels (4-15 mg/L). Microbes such as bacteria and fungi also require dissolved oxygen. These organisms use DO to decompose organic material at the bottom of a body of water. Microbial decomposition is an important contributor to nutrient recycling. However, if there is an excess of decaying organic material (from dying algae and other organisms), in a body of water with infrequent or no turnover (also known as stratification), the oxygen at lower water levels will be used up quicker.

How does pressure affect dissolved oxygen solubility?

Dissolved oxygen will increase as pressure increases. This is true of both atmospheric and hydrostatic pressures. Water at lower altitudes can hold more dissolved oxygen than water at higher altitudes. This relationship also explains the potential for "supersaturation" of waters below the thermocline - at greater hydrostatic pressures, water can hold more dissolved oxygen without it escaping. Gas saturation decreases by 10% per meter increase in depth due to hydrostatic pressure. This means that if the concentration of dissolved oxygen is at 100% air saturation at the surface, it would only be at 70% air saturation three meters below the surface.

What affects dissolved oxygen solubility?

Two bodies of water that are both 100% air-saturated do not necessarily have the same concentration of dissolved oxygen. The amount of dissolved oxygen (in mg/L) will vary depending on temperature, pressure and salinity.

What is dissolved oxygen saturation?

In a stable body of water with no stratification, dissolved oxygen will remain at 100% air saturation. 100% air saturation means that the water is holding as many dissolved gas molecules at it can in equilibrium. At equilibrium, the percentage of each gas in the water would be equivalent to the percentage of that gas in the atmosphere, which is known as its partial pressure. The water will slowly absorb oxygen and other gasses from the atmosphere until it reaches equilibrium at complete saturation. This process is sped up by aeration. It is possible for dissolved oxygen to exceed 100% air saturation in water by biological means.