-

Products

- Lab Instruments

-

Lab Meters and Probes

Calibration Standards Other Meters and Probes

- Chemistries, Reagents, and Standards

-

Online Analyzers

Ammonium Analysers Chlorine Analyzers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

- EZ Series Accessories

- EZ sc Series Inorganics

- EZ sc Series Metals

- EZ sc Series Nutrients

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analog)

- SC4500

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Pro Series

pH & ORP Sensors- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

Dissolved Oxygen Sensors- 2582sc

- 5500 Clark DO

- 9582 sc

- LDO 2 sc

- Orbisphere 311xx

- Orbisphere GA2x00

- Orbisphere K1X00

- Orbisphere M1100

- Orbisphere Oxygen ppb

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 3798 sc Electrodeless

- 9523 Cation Conductivity

- 9525 DCCP System

- Samplers

- Multiparameter Online Panels

- Test Kits & Strips

-

Microbiology

Accessories and Chemicals Dehydrated MediaInstruments KitsLabware

- Automated Lab Systems

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments- Balances

- Hot Plates & Stirrers

- Microscopes

- Moisture Analysers

- Other Instruments

- Ovens & Incubators

- Thermometers

- Timers

- Vacuum Pump

- Industrial UV

- Flow and Collections

- Electrochemistry

- Parameters

- Industries

- Support

- Service

- e-Shop

Hach India

Choose your country or region:

Europe

Americas

Asia - Australasia

- Australia

- Mainland China

- India

- Indonesia

- Japan

- Malaysia

- New Zealand

- Philippines

- Singapore

- South Korea

- Thailand (Thai)

- Taiwan

- Vietnam

Middle East - Africa

Promotions INQUIRY: +91 9916040249

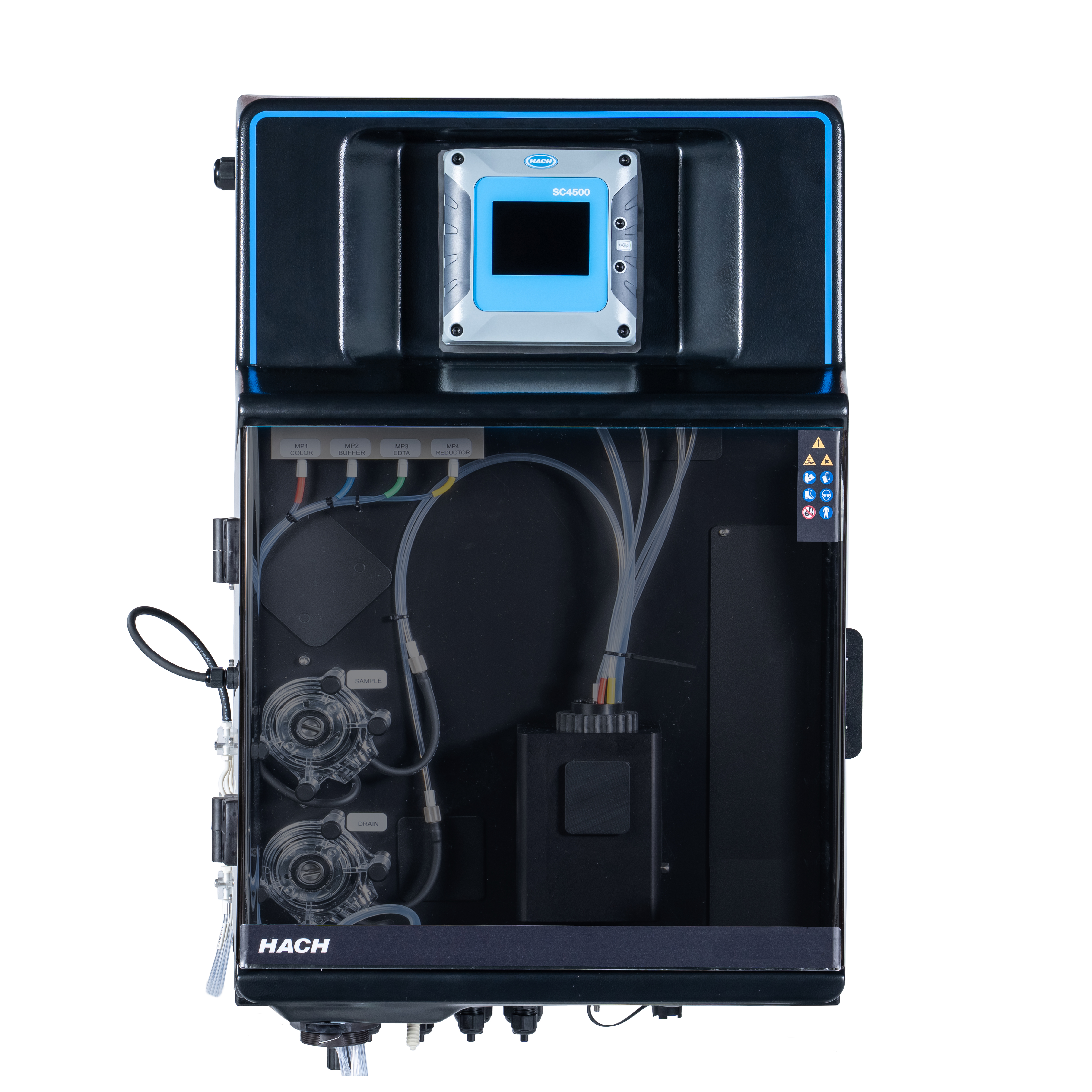

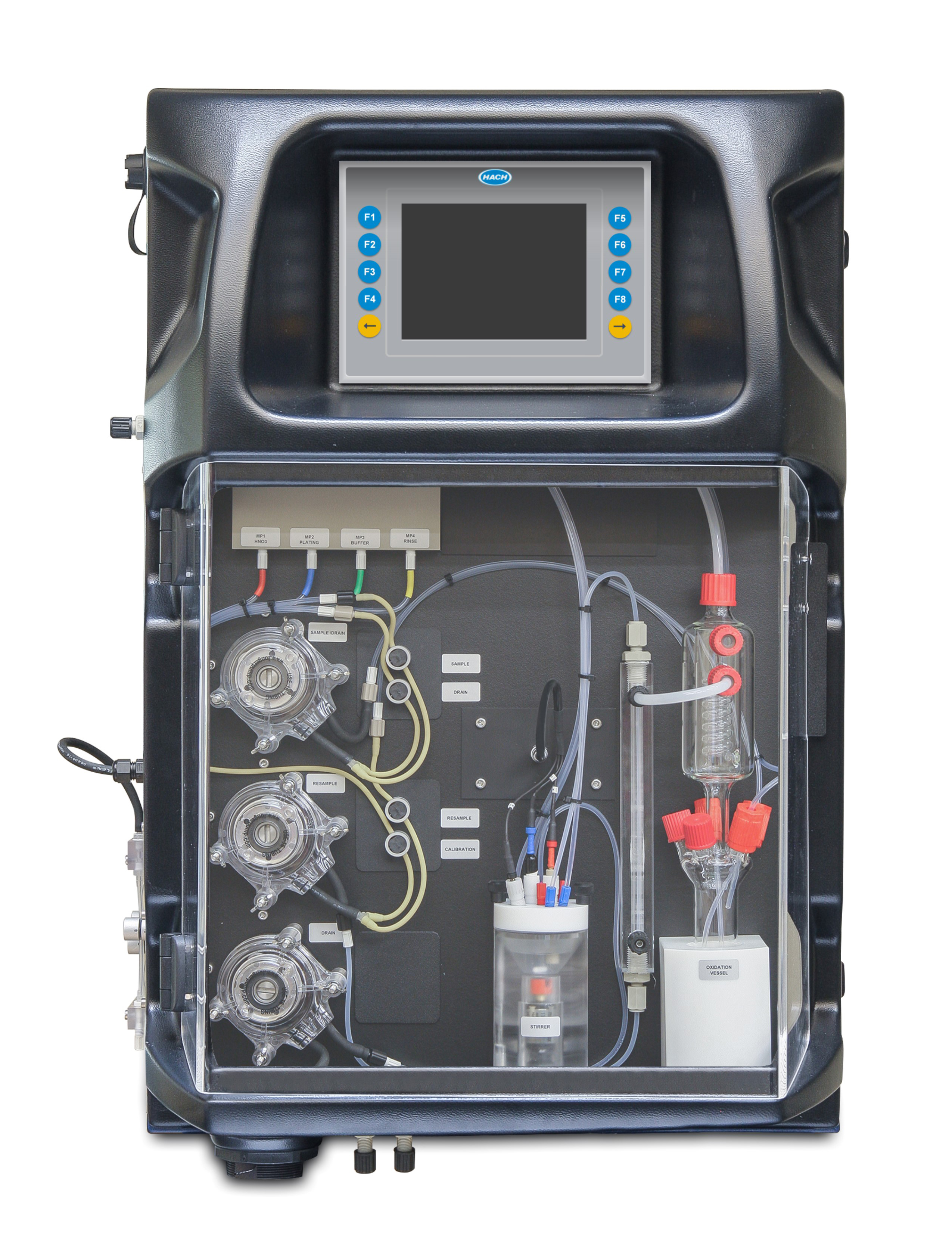

EZ Series Online Analyzers

EZ Series Online Analyzers - Water Analysis from Alkalinity to Zinc

Risk mitigation, compliance, safety, and process uptime: these are common requirements in water management in every industry. The EZ Series Online Analyzers from Hach ® provide a solution for continuously monitoring parameters that are critical to these concerns.

The EZ Series Online Analyzers include new and unique parameters, numerous measurement ranges, and provide data 24/7 – so you can make faster decisions. All instruments come in the same rugged mainframe with a compact footprint and a common user interface on industrial panel PCs, keeping training efforts low.

With continuous monitoring from EZ Series analyzers, you can detect trends and identify potential issues – before they become problems.

Maximize Insight with Minimal Effort - The NEW EZ1000sc and EZ2000sc Series

The EZ series evolves into the updated EZ sc version, improving the user experience with a more intuitive interface while maintaining the flexibility, accuracy and reliability that distinguish these online process analyzers.

The EZ sc analyzers feature:

- Additional output options (Profinet, Profibus DP, Ethernet IP)

- On-screen graphic of measurement trends

- 31 available parameters

- Multiple user access levels

- Counters, reminders and alarms for reagents consumption

- On-screen guided workflows and additional information

Wide Analytical Range

The EZ Series suite of analyzers is the complete solution for the water cycle, measuring innovative parameters such as ATP, Toxicity, VFA/TAC, and Trace Metals, along with Organics, Inorganics, and Nutrients. Whether for drinking water, wastewater or industrial applications, you can optimize a wide range of treatment processes with the EZ Series.

Flexibility

EZ Series analyzers offer you the ultimate in flexibility, with a variety of measuring ranges, multi-stream capabilities (up to 8 channels), and multiple parameter options – including total or dissolved metals. Be confident in the accuracy of your analysis, with automatic calibration and validation – or choose to introduce your own sample or standard into the analyzer via the grab-sample port.

Faster Decisions

With EZ Series technology, you can improve process control, avoid downtime, and ensure compliance with 24/7 data availability. Administrator access and activated/deactivated menu keys provide customizable access levels for data security, and a variety of analog and digital communication outputs support easy integration into your systems.

Expand Your Capabilities

Reliable monitoring of remote locations or unmanned plants allows staff to focus on other tasks. All EZ Series analyzers share spare parts thus requiring less inventory and a common user interface reduces training efforts. Automatic cleaning between samples eliminates cross-contamination. All of this adds up to improved performance in your plant.

Choose Among Five Different Technologies:

·Titration ·Colorimetry ·Chemiluminescence ·ISE ·Voltammetry

Featured Parameters

Adenosine Triphosphate (ATP)

Biological contamination of water represents a major risk to plant, equipment, and human health. Waterborne microorganisms represent a problem in many situations where water purity and hygiene are essential and where process optimization is crucial as well. Water utilities, oil & gas facilities, chemical manufacturers, data centers, bottling plants and power stations, therefore, measure microbial load to help minimize corrosion, and optimize plant performance to alert you to possible bacterial outbreaks.

ATP in Industrial Applications

- Biofilm formation is a threat to the proper functioning of cooling water systems. Bacterial activity must be monitored, and controlled by the use of biocides.

- Where biofilms can form, proper monitoring and treatment can reduce clogged or fouled filters, corrosion, and lowered oxygen (leading to lowered pH) in the process stream.

- Reverse osmosis demineralization processes are also at risk of biofilm fouling, increasing operational and maintenance costs.

ATP in Municipal Applications

- Biofiltration monitoring

- Drinking water distribution

- Online microbiological monitoring is a useful and highly sensitive tool for demonstrating Log Removal Values of various unit processes used in direct and indirect potable reuse treatment.

- Recycled water/Water reuse

Continuous Monitoring of Microbial Activity with EZ Series Online Analyzers

Traditionally, microbiological load or contamination was measured manually in a lab setting. But now, with the Hach EZ7300 online ATP analyzer, microbiological activity can be measured continuously within the process stream, delivering data that allows operators to intervene as soon as a change in the activity is observed.

The EZ7300 determines total bacterial content by measuring ATP of any type of microorganism present in the water sample. And by quantifying intracellular, extracellular and total ATP in the sample, operators can now differentiate ATP in a living cell vs ATP released from a cell that has been subject to disinfection or lysis.

The EZ7300 series can also be used to measure the effectiveness of the biocides being used in the treatment process, to optimize the dosing regime, and help avoid damage to health, environment, and infrastructure.

Applications:

- Cooling Water

- Drinking Water

- Process Water

Alkalinity & Hardness

Effective monitoring and treatment of hardness and alkalinity are key to maintaining stable water in a variety of processes. Hardness and alkalinity are used along with pH, TDS/conductivity and temperature, in the calculation of the Langelier Saturation Index (LSI) to measure water’s propensity to either corrode metals or deposit a scale in a pipe. With the data from continuously monitoring these parameters, plant operators can adjust a process to ensure compliance, avoid permit violations, maximize efficiency, control costs, and operate at the highest levels of health and safety.

Alkalinity in Wastewater

- Alkalinity is a key parameter to ensure proper biological and chemical functions in wastewater. Nitrifying bacteria are highly susceptible to changing wastewater characteristics with alkalinity being a well understood measurement that must be monitored. Alkalinity is consumed during the nitrification process and as the water becomes more acidic the pH drops. If pH levels drop below 7, nitrification rates will begin to degrade. If the pH continues to decline nitrification could be inhibited causing high levels of ammonia in the effluent.

- Microorganisms such as polyphosphate accumulating organisms (PAOs) favor environments with higher alkalinity and an optimal pH around 8. Decreasing alkalinity levels can lead to a lower phosphate uptake rate, resulting in higher levels of phosphorus leaving the secondary treatment processes.

- Buffering chemicals dosed either in biological reactors or after secondary treatment can be effectively controlled with online alkalinity monitoring to maintain optimal biological conditions and effluent pH permit requirements. Alkalinity measurements in wastewater will start to respond before pH changes occur, providing additional time for proactive operational controls to be implemented.

- Insufficient alkalinity can impact downstream process that are pH sensitive. For example, chemical phosphorus removal processes and gas chlorine disinfection can consume alkalinity and compromise effluent pH violations.

Alkalinity in Drinking Water

- In source water, high alkalinity can affect dosage of treatment chemicals like coagulants that require a lower pH. When using blending water from different sources with varying volumes and alkalinities, online alkalinity is an important parameter for proper chemical dosing.

- For Disinfection Byproduct Rule (DBPR) compliance, alkalinity is a core parameter that relates to how much TOC needs to be removed from source water to limit DBP formation. In blended waters where alkalinity (and TOC) can vary, online measurements will immediately inform the utility about any changes that may affect DBPR rule compliance.

- Corrosion control in distribution systems is top of mind for many utilities. Alkalinity is a key parameter that relates to the buffering capacity of water, which indicates how likely a pH drop is to occur. Since a drop in pH increases the probability of lead and copper entering the drinking water supply, an online alkalinity measurement will provide real-time data about corrosion parameters related to common calculations like Langelier’s Saturation Index (LSI).

- Systems that use monochloramine as measurable residual in their distribution network also track alkalinity. A consumption of alkalinity can be a leading indicator of nitrification in the distribution system, which can lead to a variety of other water quality challenges.

Alkalinity in Industrial Applications (Power, Boiler & Steam)

- In industrial applications (power generation, boiler & steam processes) monitoring alkalinity is crucial. Whether in the raw intake water, treated boiler water, or post-boiler steam condensate water being routed back for reuse, proper monitoring and management of alkalinity helps to ensure safe and efficient operations, reducing potential maintenance, and protecting infrastructure. In boiler water, alkalinity levels should be kept above 200ppm to prevent acidic corrosion, but should not exceed approx. 700ppm to avoid excessive foaming and scale formation in pipes, pumps, boilers, or other equipment.

- For DBPR compliance, alkalinity is a core parameter that relates to how much TOC needs to be removed from source water to limit DBPR formation. In blended waters where alkalinity (and TOC) can vary, online measurements will immediately inform the utility about any changes that may affect DBPR.

- Corrosion control in distribution systems is top of mind for many utilities. Alkalinity is a key parameter that relates to the buffering capacity of water, which indicates how likely a pH drop is to occur. Since a drop in pH increases the probability of lead and copper entering the drinking water supply, an online alkalinity measurement will provide real-time data about corrosion parameters related to common calculations like LSI.

- Systems that use monochloramine as measurable residual in their distribution network also track alkalinity. A consumption of alkalinity can be a leading indicator of nitrification in the distribution system, which can lead to a variety of other water quality challenges.

Applications:

- Drinking Water

- Industrial

- Power, Boiler & Steam

- Surface Water

- Wastewater

Iron

Iron is a naturally occurring mineral in both groundwater and surface water, often viewed as water quality indicator during and after the treatment process. In some process applications, iron can also act as a control. So accurate, continuous monitoring of this trace metal is crucial to maintaining quality of both plant processes and output. Whatever the source, concentrations of iron that exceed acceptable levels must be identified and removed

Iron in Drinking Water

- While it does not pose an acute health risk, elevated iron concentrations are undesirable in drinking water due to aesthetics such as taste and appearance. Iron in source water is frequently removed using a pre-oxidation step to allow iron to be converted to an insoluble form that can be settled out during sedimentation. Oxidant (such as ozone, chlorine dioxide, permanganate, chlorine) dosing can be efficiently controlled with an online free or total iron measurement. Permanganate dosing can be monitored to prevent overdosing and making pink water. A dual stream online analysis can also show before and after values to demonstrate how much iron is (or isn’t) removed.

Iron in Wastewater

- Metal salts such as ferric chloride are used in phosphorus removal systems and can be dosed at various locations in the treatment process. While orthophosphate (PO4) is the typical measurement used to monitor chemical phosphorus removal efficiency and to control dosing, a facility may also be interested in measuring residual iron to protect downstream processes, such as scale prevention in UV disinfection equipment.

Continuous Monitoring of Iron with EZ Series Online Analyzers

The measurement of iron by colorimetry is represented by the Hach EZ1000 and EZ2000 series models in a variety of measurement ranges. The EZ Series analyzers are capable of measuring total or dissolved concentrations, and have optional multi-stream capability, as well a grab sample port for introducing grab sample into the instrument.

EZ Series online analyzers can monitor various points within the deferrization process and can be used to monitor and confirm initial lab results in iron concentrations before the actual treatment process. After the removal process, measurements can confirm that any remaining traces of the parameters exist in concentrations that meet permit requirements.

EZ series offers automatic and trouble-free measurement of iron at several stages of the process, offering an elegant solution to iron measurement and treatment.

Applications:

- Drinking Water

- Power and Steam Generation

- Surface Water

- Wastewater

Fluoride

Fluoride is found naturally in soil, water, and foods. It is also produced synthetically for use in drinking water, toothpaste, mouthwashes and various chemical products. Naturally occurring fluoride exists in all oceans, surface water, and groundwater sources, at concentrations from 0.1 to 13 mg/L.

Fluoride in Drinking Water

- When maintained and dosed at the determined appropriate level, the occurrence of fluoride in drinking water has positive effects. Studies have shown that adding it in areas where fluoride levels in the water are extremely low can reduce the prevalence of tooth decay in the local population through demineralization and remineralization. For example in the United States, fluoride is often added to drinking water but concentration may not exceed 4 mg/L in public water supplies, and most utilities keep this concentration below 1 mg/L. In Europe and other parts of the world, the addition of fluoride to drinking water is not common.

Fluoride in Industry and Wastewater

- Fluoride can be commonly discharged as effluent in many chemical industries and be a challenge for industries using hydrofluoric acid (HF) as a cleaning agent or etchant, such as the semiconductor, solar cell and metals manufacturing industries. When fluoride concentrations are too high in biological wastewater treatment systems, it can be toxic to bacterial colonies. Studies indicate that anaerobic microorganisms involved in various metabolic steps of treatment or anaerobic digestion processes are very sensitive to the presence of fluoride; in addition, fluoride can inhibit the nitrification process. An excess of fluoride in effluent discharge may represent a health hazard, so treatment is necessary to reduce concentrations to an acceptable level.

Applications:

- Drinking Water

- Chemical Processing

- Industrial Applications

- Process Water

- Surface Water

Manganese

Manganese is a trace mineral, naturally occurring in both groundwater and surface water. Too much manganese can affect color and taste in drinking water and bottled water beverage applications and can cause staining in fixtures and laundry. So accurate, continuous monitoring of both total and dissolved manganese is crucial to maintaining quality. Whatever the source, concentrations that exceed acceptable levels must be identified and managed.

Manganese in Drinking Water

- Similar to iron, manganese is also a nuisance component that can have adverse effects on the taste and the appearance of drinking water. Monitoring manganese in real time allows for the utility to adjust oxidant dosing to get the right amount without overdosing or underdosing. Oxidant (such as ozone, chlorine dioxide, permanganate, chlorine) dosing can be efficiently controlled with an online free or total iron measurement. Permanganate overdosing can be monitored to prevent overdosing and making pink water. A dual stream online analysis can also show before and after values to demonstrate how much manganese is (or isn’t) removed.

Continuous Monitoring of Manganese with EZ Series Online Analyzers

EZ Series Online Analyzers from Hach monitor a range of concentrations of both total and dissolved manganese, using colorimetry.

Currently serving in hundreds of industrial and municipal water applications, EZ Series Online Analyzers allow continuous online monitoring and a matching correlation with standard/laboratory wet-chemical methods, at a high level of precision and accuracy.

This allows you to monitor various points within your process and confirm initial lab results before the actual treatment process. After the removal process, measurements can confirm that any remaining traces of manganese exist in concentrations that meet permit requirements.

Applications:

- Drinking Water

- Power and Steam generation

- Surface Water

Toxicity

Toxicity refers to the admixture of conventional pollutants as well as toxic chemicals such as heavy metals, organic compounds, oxidants, etc. that can be found in waste streams destined for treatment. The source of these toxic compounds can be from a variety of conventional or industrial effluent discharges and can vary in concentration and toxic effects produced.

Toxicity in Wastewater

- Toxic influent can be detrimental to the Wastewater Treatment Plant (WWTP) by inhibiting or damaging the bacterial colonies in the plant’s treatment process. When toxic, the influent can damage the active sludge which will hinder the efficiency of nutrient and COD/BOD removal processes.

- During a toxicity measurement the respiration rate of bacteria is being monitored in a controlled environment. The respiration rate is defined as the amount of oxygen bacteria consume per hour and it is this respiration rate which is affected by toxic influent entering the WWTP. There are components that can enter the WWTP which are under normal conditions harmless to bacteria but when present in too high concentrations suddenly become a threat to the WWTP.

- Given the challenging and tedious grab sample methods currently available, facilities can save themselves time and challenging circumstances that stem from plant upsets by monitoring at the very beginning of the process and catching unforeseen problems or toxic events early on.

Toxicity in Other Applications

- Companies that run WWTPs at a chemical factory or refinery.

- Facilities that operate industrial wastewater plants.

- Companies that run tank storage farms.

- Municipal plants that receive industrial wastewater for processing.

The EZ7900 Toxicity Analyzer uses a comparison between respiration rate of a healthy sludge sample vs a toxic spiked sludge sample to calculate an index that determines the level of inhibition caused by the potentially toxic influent.

Applications:

- Chemical

- Refineries

- Storage

- Wastewater

Total Nitrogen and Total Phosphorus (TN & TP)

Excess nutrients (nitrogen and phosphorus) in the environment can lead to harmful algae blooms, eutrophication, and an overall decline in water quality. While most online monitoring solutions focus on specific subsets of these nutrients (i.e. ammonia, nitrate, ortho-phosphate, etc.,) the regulatory requirements can be written around the total forms (TN/TP). Thus, automatic, continuous monitoring of TN and TP in the process stream provides time-saving capabilities, can correlate process values to lab results, and can alert plant operators to issues without waiting for lab results. In an era of increasingly stringent effluent guidelines, monitoring your treatment process at critical points can point out process adjustments that are necessary to maintain compliance.

TN and TP in Wastewater

- Total nitrogen (TN) in wastewater consists of ammonia/ammonium (NH 3/NH 4 +), nitrates (NO 3), nitrites (NO 2), and organic nitrogen. TN is simply a summation of all forms. Many effluent permits only require a reduction of the ammonia levels. In other cases, the effluent permit may require a reduction of all forms of nitrogen. This would be reflected by having a (TN) limit set on the discharge permit. Since nitrogen cannot be simply removed chemically, these facilities will have to manage their biological processes to do the job. This is generally referred to as biological nutrient removal (BNR). In such cases, it is desired to keep a close eye on the process via an effluent monitoring system. In other cases, an influent monitoring system is also recommended for TN, as well as for the individual forms of nitrogen.

- Total phosphorus (TP) in wastewater consists of dissolved and particulate forms. The most common form of soluble phosphorus is orthophosphate (reactive). Particulate phosphate is most commonly in the form of polyphosphate or organic phosphate. The summation of all forms is TP. Many plants have a requirement to reduce all forms of phosphorus. Phosphorus is removed by combining it into a settleable solid form and removing it with the waste sludge. This can be achieved either via biological uptake (Bio‐P or eBPR) or chemical precipitation (typically with alum or ferric).

TN and TP in Surface Water

- For environmental health of surface water, treatment levels can prevent eutrophication of receiving bodies of water, as TP is used as an indicator of organic forms of phosphorus in surface water. Combined measurement of TN and TP gives operators a predictor of algae growth.

Continuous Monitoring of TN and TP with EZ Series Online Analyzers

The EZ7600 from Hach, combines two methods for the simultaneous, automatic measurement of TN and TP. With a wide measurement range, and optional multiple-stream analysis, this innovative instrument is a convenient solution for your TN/TP monitoring needs. For customers who don’t need a multiple-parameter analyzer, the EZ7700 or EZ7800 Analyzers offer singe-parameter measurement for TN and TP, respectively.

Applications:

- Surface Water

- Wastewater

Volatile Fatty Acids (VFA)

Volatile fatty acids (VFA) can be a helpful parameter for monitoring certain processes that could be taking place in a water resource recovery facility. When coupled with alkalinity, VFA can be a key parameter for monitoring anaerobic digester health. An increase in VFA and/or a decrease in sludge alkalinity can create an imbalance and indicate potential anaerobic digester operational issues which, without taking action, can result in digester upsets. While VFA are not desirable in excess in an anaerobic digester, they can be a benefit to facilities that perform enhanced biological phosphorus removal (EBPR). VFA are an important carbon source for the bacteriological population responsible for effective biological phosphorus removal.

VFA in Wastewater

- VFA measured in real-time in anaerobic digestion systems, coupled with alkalinity and pH, produces a data stream that provides the highest level of visibility to a treatment facility. This data provides early, proactive measurements to allow for process or operational changes to avoid digester upsets. Online measurement of these parameters and automatic calculation of the VFA to alkalinity ratio further enhances process control and troubleshooting.

- Within green energy projects, monitoring VFA and alkalinity – (along with proper data interpretation and process adjustments) can help maximize production of biogas. These biogas facilities can be optimized to produce more and higher quality gas that is used for electricity, heat and clean natural gas fuel.

- VFA are considered paramount for effective biological phosphorus treatment. Sludge fermentation is a proven process to increase VFA concentrations into the secondary treatment system. There are several fermentation processes that are being implemented in treatment facilities that treat for phosphorus biologically, including inline primary clarifier fermentation and offline complete mix fermentation. With online VFA measurements, primary sludge fermentation processes can be monitored and optimized in real time. Increased VFA production in these EBPR systems will lead to increased system stability, reducing or eliminating the need for additional chemical polishing.

Applications:

- Wastewater

Service Partnership

With Hach Service, you have a global partner who understands your needs and cares about delivering timely, high-quality service you can trust. Our Technical Support, Field Service, and Central Service Teams work together with unique expertise to help you maximize instrument uptime, ensure data integrity, maintain operational stability, and reduce compliance risk.