-

Products

- Lab Instruments

-

Lab Meters and Probes

Calibration Standards Other Meters and Probes

- Chemistries, Reagents, and Standards

-

Online Analyzers

Ammonium Analysers Chlorine Analyzers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

- EZ Series Accessories

- EZ sc Series Inorganics

- EZ sc Series Metals

- EZ sc Series Nutrients

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analog)

- SC4500

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Pro Series

pH & ORP Sensors- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

Dissolved Oxygen Sensors- 2582sc

- 5500 Clark DO

- 9582 sc

- LDO 2 sc

- Orbisphere 311xx

- Orbisphere GA2x00

- Orbisphere K1X00

- Orbisphere M1100

- Orbisphere Oxygen ppb

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 3798 sc Electrodeless

- 9523 Cation Conductivity

- 9525 DCCP System

- Samplers

- Multiparameter Online Panels

- Test Kits & Strips

-

Microbiology

Accessories and Chemicals Dehydrated MediaInstruments KitsLabware

- Automated Lab Systems

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments- Balances

- Hot Plates & Stirrers

- Microscopes

- Moisture Analysers

- Other Instruments

- Ovens & Incubators

- Thermometers

- Timers

- Vacuum Pump

- Industrial UV

- Flow and Collections

- Electrochemistry

- Parameters

- Industries

- Support

- Service

- e-Shop

Hach India

Choose your country or region:

Europe

Americas

Asia - Australasia

- Australia

- Mainland China

- India

- Indonesia

- Japan

- Malaysia

- New Zealand

- Philippines

- Singapore

- South Korea

- Thailand (Thai)

- Taiwan

- Vietnam

Middle East - Africa

Promotions INQUIRY: +91 9916040249

Claros Process Management

Continuous process management solutions allow you to manage your treatment processes in real time, keeping your facility compliant while ensuring efficient plant operation 24/7. Managing your process has never been so straightforward.

See Claros Solutions

- Instrument Management

- Data Management

- Process Management

Which processes are you looking to improve?

Do you wish you had more real-time visibility into your process?

Do you have compliance concerns around BOD/COD removal?

Do you have problems with sludge settleability resulting in compliance concerns?

Are you looking to reduce your aeration energy costs?

Do you target a fixed mixed liquor suspended solids (MLSS) value or are you adjusting sludge retention time (SRT)?

Having the correct C/N/P balance is critical for biological wastewater treatment. Hach’s RTC C/N/P system optimises the dosing of nutrients like urea and phosphoric acid in industrial wastewater treatment plants, ensuring compliance on COD / BOD, NH4 and PO4. Cost for effluent discharges and on chemicals added are driven to an absolute minimum.

Relevant Solutions:

Nutrient Dosing (RTC-C/N/P)

Having the correct C/N/P balance is critical for biological wastewater treatment. Hach’s RTC C/N/P system optimises the dosing of nutrients like urea and phosphoric acid in industrial wastewater treatment plants, ensuring compliance on COD / BOD, NH4 and PO4. Cost for effluent discharges and on chemicals added are driven to an absolute minimum.

Sludge Retention Time (RTC-SRT)

A correct Sludge Retention Time and Mixed Liquor Suspended Solids level in the aeration basin is fundamental for compliance and energy efficient treatment. Hach’s RTC-SRT system automatically adjusts the waste activated sludge to provide the ideal SRT and MLSS concentration ensuring stable BOD/COD removal and avoiding undesired Nitrification.

Most Open Valve DO Control (RTC-MOV)

Energy efficient aeration systems (blowers and valves) provide and distribute the process air at a minimum air pressure in the manifold and a minimum pressure loss across the air valves. The Hach RTC-MOV system controls the DO concentration in up to 16 different zones by providing set points for the corresponding air valve positions and for the manifold pressure (or airflow). The result is reduced costs and maximum available process air where it is needed most.

Modified Solutions

Not seeing a solution that exactly meets your need? Contact us to discuss potential options for your specific challenges.

Do you wish you had more real-time visibility into your process? Do you know your maximum nitrification capacity and what rate is required right now?

Do you have compliance concerns around ammonium or total nitrogen treatment?

Are you applying static DO concentrations or do you adjust based on load?

Are you applying fixed aeration/amoxic times or volumes, or are you adjusting based on actual purification requirements?

Do you target fixed mixed liquor suspended solids (MLSS) or are you adjusting sludge retention time (SRT)?

Based on real-time data like those for flow, NH 4-N, NH 3-N, DO and MLSS, Claros Process Management systems continuously monitor the actual inflow load and plant performance. Using those evaluations, dynamic set points -- including those for DO concentrations, aeration intensity, internal recirculation, anoxic time or sludge retention time – are calculated to safeguard compliance and ensure efficient plant operation 24/7.

Relevant Solutions:

Nitrification and Denitrification through On/Off control (RTC-N/DN)

Meeting Total Nitrogen (TN) limits in the effluent of intermittent-operated plants can be very challenging. Varying inflow conditions can hardly be managed with fixed time periods for nitrification and denitrification. The RTC-N/DNSBR system, designed for intermittent operated sequencing batch reactors, determines optimal times for nitrification and denitrification based on the continuous measurement of NH 4-N and NH 3-N. Through this, Nitrogen elimination is maximised while aeration energy is minimised.

Sequencing Batch Reactor (SBR) (RTC-N/DNSBR)

Meeting Total Nitrogen (TN) limits in the effluent of plants utilising simultaneous nitrification can be very challenging. Varying inflow conditions can hardly be managed with fixed volumes for nitrification and denitrification. The RTC-SND system determines the optimal aerobic and anoxic volume based on the continuous measurement NH 4-N and NH 3-N. Through this, Nitrogen elimination is maximised while aeration energy is minimised

Simultaneous Nitrification/Denitrification (RTC-SND)

Meeting the NH 4-N limits in the effluent of a nitrifying plant with plug flow reactors can be very challenging. Varying inflow conditions can hardly be managed with a fixed DO concentration in the aeration tank. Based on the measured NH 4-N inflow load and NH 4-N effluent concentration the N-RTC calculates DO setpoints ensuring immediately reaction on inflow load changes and precise control of the NH 4-N effluent concentration to a desired setpoint. Through this, compliance on NH 4-N is ensured while aeration energy is minimised.

Nitrification (RTC-N)

Meeting the NH 4-N limits in the effluent of a nitrifying plant with plug flow reactors can be very challenging. Varying inflow conditions can hardly be managed with a fixed DO concentration in the aeration tank. Based on the measured NH 4-N inflow load and NH 4-N effluent concentration the N-RTC calculates DO setpoints ensuring immediately reaction on inflow load changes and precise control of the NH 4-N effluent concentration to a desired setpoint. Through this, compliance on NH 4-N is ensured while aeration energy is minimized.

Most Open Valve DO Control (RTC-MOV)

Energy efficient aeration systems (blowers and valves) provide and distribute the process air at a minimum air pressure in the manifold and a minimum pressure loss across the air valves. The Hach RTC-MOV system controls the DO concentration in up to 16 different zones by providing set points for the corresponding air valve positions and for the manifold pressure (or airflow). The result is reduced costs and maximum available process air where it is needed most.

Denitrification (RTC-DN)

Meeting Total Nitrogen (TN) limits in the effluent of wastewater treatment plants requires the best usage of the available denitrification capacity. For plants with internal recirculation this means only a minimum of DO has to be carried over from the nitrification to the denitrification zone. This can hardly be achieved with a fixed or inflow proportional internal recirculation flow rate. Designed for plants with internal recirculation the RTC-DN system ensures that the available denitrification capacity is utilised by controlling the NH3-N concentration effluent denitrification or effluent aeration to a desired setpoint. If required, dosing of external carbon sources can also be controlled to support denitrification. Through this, compliance on TN can be supported while potential costs for external Carbon are minimised.

Denitrification - Swing Zone (RTC-SZ)

The swing zone controller works in conjunction with the RTC-N to provide maximum available DN volume. Then, the plant load allows nitrification volume to be safely reduced. Zone 1 of an aeration lane can be reliably switched to anoxic, greatly increasing the denitrification potential of a plant. Alternatively, this can be used to introduce/extend a selector zone into plants to help improve sludge settleability.

Sludge Retention Time (RTC-SRT)

A correct Sludge Retention Time and MLSS level in the aeration basin are fundamental for compliance and energy efficient treatment. Hach’s RTC-SRT system automatically adjusts the waste-activated sludge to provide the ideal SRT and MLSS concentration, thus ensuring stable Nitrification all year around.

Modified solutions

Not seeing a solution that exactly meets your need? Contact us to discuss potential options for your specific challenges.

Do you wish you had more real-time visibility into your process?

Are you adding chemicals based on static dosing rate or are you adjusting according to load?

Do you have compliance concerns with load peaks?

Do you foresee lower permit requirements on the horizon?

Are there times you struggle with biological phosphorus removal (Bio-P)?

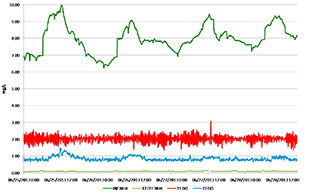

Based on real-time data like those for flow, orthophosphate or total phosphorous, Claros Process Management systems continuously monitor the actual inflow load and plant performance. Using those evaluations, dynamic set points -- including precipitant dosing rates at any point in the plant – are calculated to safeguard compliance and to ensure efficient plant operation 24/7.

Relevant Solutions:

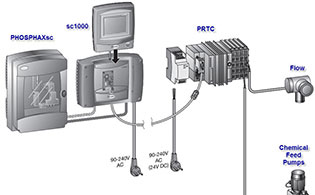

PO 4-P Precipitation (RTC-P)

Meeting the Total Phosphorus (TP) limit in the effluent of plants with chemical PO 4-P elimination can be very challenging. Varying inflow loads can hardly be managed with a fixed dosing rate of precipitant. Based on the measured PO 4-P, the RTC-P system calculates a setpoint for the precipitant dosing rate, ensuring fast reaction on inflow changes and precise control of the PO 4-P concentration to a desired setpoint. Through this, compliance on TP is supported while cost on precipitant and the amount of precipitation sludge is minimized.

Do you wish you had more real-time visibility into your process?

Is your sludge thickening or dewatering process consistent?

Are you satisfied with the capture rate of your thickening or dewatering process?

Do you experience problems with your sidestreams?

Are you adding polymer based on static dosing rate or are you adjusting in real time according to load?

The cost of sludge treatment in wastewater is influenced by the concentration of thickened, floated or dewatered sludge, as well as by the usage of polymer and coagulant. Based on real-time data like those for flow, TOC, Dissolved Oxygen (DO), and MLSS, Claros Process Management systems continuously monitor the actual inflow load and plant conditions. Using those evaluations, dynamic set points -- including those for dosing of external nutrient sources, aeration intensity and sludge retention time – are calculated to safeguard compliance and ensure efficient plant operation 24/7.

Relevant Solutions:

Sludge Thickening (RTC-ST)

High gas yield in anaerobic sludge digestion, consistent thickened/dewatered sludge, and low operating costs are core objectives in sludge thickening. This can be achieved with the RTC-ST system which manages Total Suspended Solids (TSS) in thickened sludge and filtrate by adjusting polymer dosing.

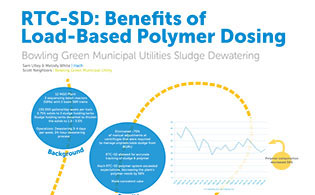

Sludge Dewatering (RTC-SD)

Low cost for sludge disposal, minimum negative impact on returns, and low polymer consumption are core objectives in sludge dewatering. The RTC-SD system can achieve this by managing Total Suspended Solids (TSS) in thickened sludge and centrate by adjusting polymer dosing.

Dissolved Air Flotation (RTC-DAF)

High Total Suspended Solids (TSS) concentration in the sludge and low TOC/TSS concentration in treated effluent are core objectives in Dissolved Air Flotation (DAF). This can be achieved with the RTC-DAF system which controls TSS in the thickened sludge and discharge effluent by correctly adjusting pH, coagulant and polymer dosing.

Modified solutions

Not seeing a solution that exactly meets your need? Contact us to discuss potential options for your specific challenges.

“Prior to installing Claros Process Management, we were looking at continuing the status quo of running a manual system. We were talking about hiring another DAF Attendant. Claros Process Management has helped keep us in compliance and we haven’t had any issues since it has been running consistently.”

– Operations Maintenance Manager

“We let Hach take control almost immediately. If there was a component failure, operators had the contingency that the RTC-N would go to a default DO setpoint or the operators could go back to manual control. So, there wasn’t any hesitation from operators to put the system online.”

- Agency Staff Member, California (USA)

Curious? Find out what Claros can do for you today.

HOW CAN WEHELP YOU?

Resources

Real-life applications of Claros solutions

BROCHURE: RTC In-Depth Product Overview

Product range and descriptions for Real Time Control modules

APPLICATION NOTE: RTC for Phosphorus Removal In North Las Vegas (USA)

Automated phosphorus monitoring and treatment control maintains reclamation-quality discharge