-

Products

- Lab Instruments

-

Lab Meters and Probes

Calibration Standards Other Meters and Probes

- Chemistries, Reagents, and Standards

-

Online Analyzers

Ammonium Analysers Chlorine Analyzers

- CL17sc

- CL10sc Amperometric

- 9184 sc Amperometric

- Ultra Low Range CL17sc Colorimetric Chlorine Analyser

EZ Series Analysers- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

- EZ Series Accessories

- EZ sc Series Inorganics

- EZ sc Series Metals

- EZ sc Series Nutrients

-

Online Sensors and Controllers

Digital Controllers (Transmitters) Controllers (Analog)

- SC4500

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

- Pro Series

pH & ORP Sensors- 1200-S pH

- 12mm pH/ORP

- 8362 sc High Purity

- Combination pH/ORP

- Differential pH

- Digital Differential ORP

- Digital Differential pH

- LCP ORP

- LCP pH

Dissolved Oxygen Sensors- 2582sc

- 5500 Clark DO

- 9582 sc

- LDO 2 sc

- Orbisphere 311xx

- Orbisphere GA2x00

- Orbisphere K1X00

- Orbisphere M1100

- Orbisphere Oxygen ppb

Conductivity Sensors- 3400 Analogue Contacting

- 3400 Digital Contacting

- 3700 Analogue Inductive

- 3700 Digital Inductive

- 3798 sc Electrodeless

- 9523 Cation Conductivity

- 9525 DCCP System

- Samplers

- Multiparameter Online Panels

- Test Kits & Strips

-

Microbiology

Accessories and Chemicals Dehydrated MediaInstruments KitsLabware

- Automated Lab Systems

-

Lab Equipment and Supply

Apparatus

- Brushes

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Other Apparatus

- Pipet Aids

- Pipettes

- Racks

- Stir Bars

- Tubing

- Weighing Accessories

General Lab Consumables Glassware/PlasticwareInstruments- Balances

- Hot Plates & Stirrers

- Microscopes

- Moisture Analysers

- Other Instruments

- Ovens & Incubators

- Thermometers

- Timers

- Vacuum Pump

- Industrial UV

- Flow and Collections

- Electrochemistry

- Parameters

- Industries

- Support

- Service

- e-Shop

Industry - Drinking Water

Drinking Water

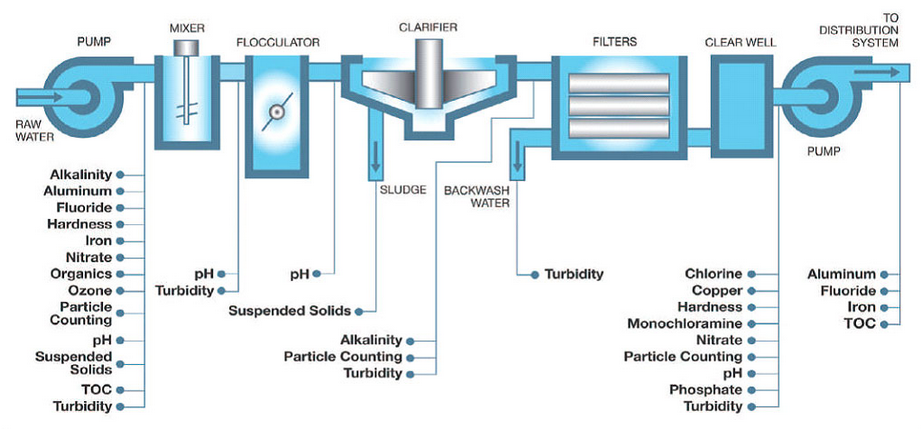

The demand for clean drinking water is expanding together with the globe’s population. Regardless of its origin, drinking water must be treated and tested to ensure its safety. There are many processes that take place before drinking water reaches the faucet and testing all of these, from the watershed to the distribution system.

Hach commits to safeguarding your drinking water facilities round the globe and offer you pioneering solutions through monitoring your water quality, ensuring better efficiency for the plant, reduction of costs, and safer drinking water for the community.

- We provide our expertise in

- Source Water Monitoring

- Coagulation, Flocculation, & Clarification

- Filter Monitoring

- Disinfection Process Control

- Disinfection Byproduct Reduction

- Distribution Monitoring

Drinking Water process and monitoring solution we are offering

Source Water Monitoring

Source water can be vulnerable to accidental or intentional contaminants and weather related or seasonal changes. Monitoring the quality of your incoming source water enables you to anticipate changes to the treatment process that are needed to react to storms, algal blooms, industrial discharge, chemical spills, reservoir stratification/destratification, construction activity, sewage spills and other natural or man-made occurrences.

Groundwater

Groundwater is the source water for the majority of small drinking water facilities. Groundwaters are usually low in organic matter, which makes disinfection byproduct formation not of concern. Groundwater, however, does contain compounds that, while not harmful for human consumption, can provide treatment challenges to systems that are using chlorine for the first time.

Surface Water

Surface water is the source water for the majority of people served with potable water. Surface water generally includes lakes, rivers and reservoirs. Because surface water is exposed to natural and man-made influences, it has a broader exposure to organic matter responsible for disinfection byproduct formation.

Blending of Source Waters

Blending is the mixing of two or more source waters. Blending can include a raw source water or treated water and is a strategy chosen due to water availability or to achieve certain water quality objectives. This section focuses on parameters needed when treated waters are used in blending and only parameters that affect the disinfection process.

Coagulation, Flocculation, and Clarification

Coagulation, flocculation, and clarification are perhaps the most overlooked processes when installing instrumentation in a water treatment facility. This may be due to the fact that monitoring at these points is typically not a regulatory requirement. However, every step in the treatment process depends on preceding steps and those that follow to make the entire process function effectively. Measurement is critical at every step to optimize the process and control operational costs.

Back to top

Filter Monitoring

Monitoring turbidity of filter effluent is required for regulatory compliance in many countries and helps to assure that the final product is safe for public consumption. In addition to meeting regulatory requirements, monitoring turbidity is also beneficial for optimizing filter performance, establishing filter backwash cycles, and detecting filter breakthrough. Turbidity instrumentation is available to meet the unique needs of both conventional and membrane filtration facilities.

Back to top

Disinfection Process Control

Regardless of the type of disinfectant used, analytical testing can help you comply with regulations, maximize disinfection efficiency, determine adequate CT credits, optimize chemical feed pump rates, reduce the risk of disinfection byproducts, and control taste and odor issues. A wide range of analytical methods and instrumentation is available to address the specific needs of each unique plant.

Free Chlorine

Although the pros and cons of disinfection with chlorine have been extensively debated, it remains the most widely used chemical for disinfection of water in the U.S. Chlorine is primarily used as a disinfectant, but also serves as an oxidizing agent for taste and odor control, prevention of algal growths, maintaining clear filter media, removal or ion and manganese, destruction of hydrogen sulfide and improving coagulation.

Chloramines

Free Chlorine is often replaced with chloramines as a secondary disinfectant due to its long lasting residuals and when trihalomethanes or other disinfection by-products are a problem. In chloramination disinfection, monochloramine is formed from the reaction of ammonia with chlorine. In general, ammonia is added first or simultaneously with the chlorine to reduce the formation of chlorinated organic compounds.

Other Disinfectants

The treatment processes for drinking water have changed during the last several years as increased concerns about disinfection byproducts and water borne pathogens have become more prevalent. Many treatment processes now incorporate multiple oxidants or disinfectants to address these increased concerns. Other treatment objectives for these multiple oxidants include reducing taste and odor problems and facilitating the removal of iron and manganese.

Back to top

Disinfection Byproduct Reduction

Advanced analytical techniques are available to identify the specific disinfection byproducts formed in the treatment process and the distribution system. These techniques are beyond the technical and economic resources available at most facilities. Fortunately, alternate methods are available for screening for disinfection byproducts and for predicting disinfection byproduct formation that can be used routinely by most facilities with limited resources.

Back to top

Distribution Monitoring

Monitoring specific parameters in the distribution system is commonly a regulatory requirement to assure delivery of safe drinking water to the community. Additional monitoring can also provide early indication of nitrification issues, water infiltration, line breaks, extended water age, or potential security violations.

Back to top